Breaking news and analysis

Как пройти регистрацию на Vavada пошагово

ינואר 25, 2024Gmail: veilig en privé e-mailen zonder kosten

אפריל 5, 2024

The system underlines LOD 3 on balance sheet reports and LODs 3 and 4 on income statement reports. When there is an increase in customer sales, it means that there is higher demand. A company then needs to produce more of its products to meet this new demand which, in turn, raises the break-even point in order to cover the extra expenses. As a result of these technological advancements, businesses can achieve greater scalability and adaptability—essential factors for driving growth in today’s fast-paced market environment. Process costing is beneficial for saving time as calculating costs need not to be completed for each individual unit. The downside is that the costs per unit can become inaccurate since rounding up costs per process can introduce discrepancies.

The Three Critical Components of Manufacturing Costs

- The difference between the planned and actual labor costs, based on the work order routing.

- Technology significantly enhances the role of accounting in manufacturing by streamlining processes and increasing efficiency.

- Visit Department of Energy’s Vehicle Technologies Office to learn about the future of EV batteries.

- By partnering with specialized accounting providers, manufacturing firms can ensure efficiency, compliance, and financial clarity without overburdening their internal teams.

- Manufacturing businesses often use multiple software systems for production, inventory management, and accounting.

- Understanding competitive positioning helps in making informed decisions based on the unique strengths and strategic focuses of key players.

Domestic OEMs such as BYD and Geely already offer twice as many electric models than conventional models. This is in contrast to the offering from OEMs headquartered elsewhere in the world, which have slightly fewer electric than ICE models available in China. However, this balance is https://sistemaaqv.metodoaqv.com.br/2024/05/03/net-new-business-definition/ likely to shift in favour of electric by 2030, with around 80 additional electric models announced.

Are you looking for a professional advisor for your business?

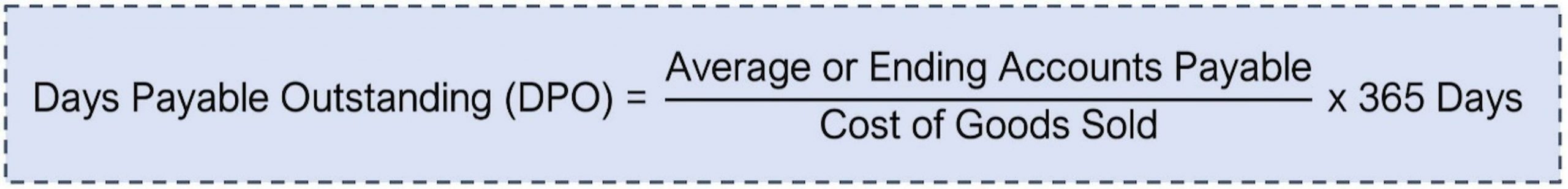

Regularly reviewing and updating cost assumptions, as well as maintaining flexibility in your accounting systems, can help to mitigate these risks. We use manufacturing accounting job order costing when we manufacture products based on specific customer orders. These three metrics are used together to allow a business to see their profitability, get a better understanding of production costs, and manage inventory better through data. They are also able to see where improvements need to be made, such as pricing for slower-moving products.

- This permits manufacturers to make strategic decisions and prevent pricey mistakes.

- You agree not to copy, reproduce, modify or distribute the Content without express consent from Sage.

- Verstela Staffing delivers staffing solutions across the country to businesses just like yours.

- Manufacturing firms often process a high volume of transactions daily, including purchases of raw materials, labor costs, production overheads, and sales of finished goods.

- Our guidance helps manufacturers enhance margins without compromising product quality.

- Our commitment to quality research and client success has established us as a trusted name in global market intelligence.

Providing Reports for Decision-Making

An integral component of manufacturing accounting lies in efficient inventory management. Supply chain efficiency directly influences manufacturing costs, making supplier performance a key financial consideration. Manufacturers can use financial data to track supplier pricing trends, lead times, and material quality to identify cost-saving opportunities and mitigate risks. By reviewing variance reports on material costs and defect rates, manufacturers can quantify the financial impact of supplier inconsistencies, helping them negotiate better contracts or seek alternative vendors. Beyond cost tracking, ERP systems enhance cash flow management by synchronizing accounts payable and receivable with production schedules.

Overview to Manufacturing Accounting

Establish a routine for generating financeial reports such as income statements, balance sheets, and cash flow statements. Conduct monthly reviews to identify trends and monitor performance against budgets. Ensure all transactions are promptly recorded and reconciled with bank statements. Regularly review and update your chart of accounts to reflect any changes in your manufacturing In-House Accounting vs. Outsourcing operations. Hanging on to outdated or inaccurate financial information creates a murky picture of your financial health.